@ FOOTWEAROLOGY LAB BARCELONA - LEVEL: INTERMEDIATE/ADVANCED

Open Lab weeks!

Dates: August 19-30, 2024

So many of our course participants have asked if they could please stay longer at our lab, so they could use our machines to work on their own projects or just to experiment with some new ideas. Since we have now expanded both our team and the number of machines, we can finally offer this possibility!

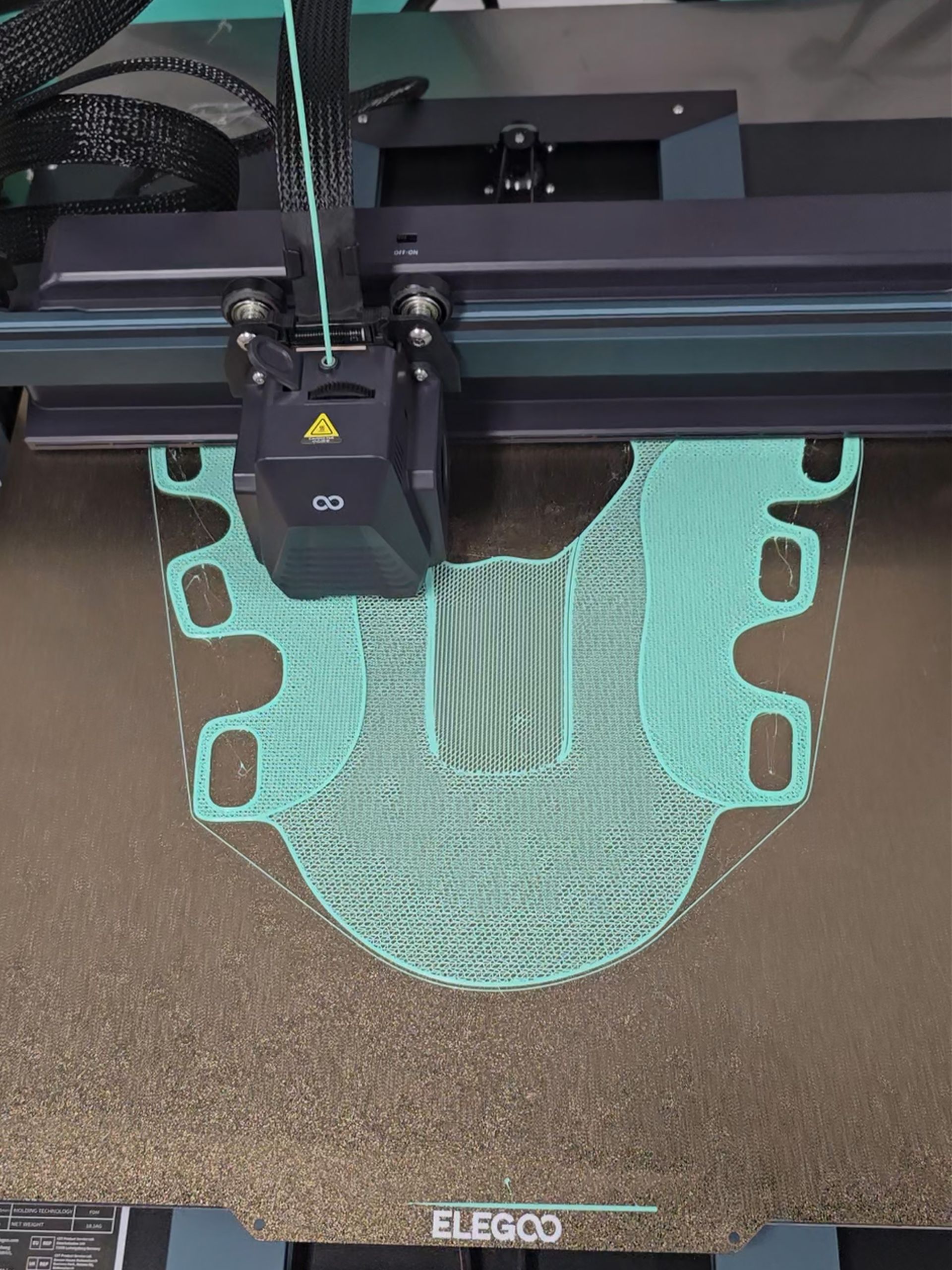

In the last two weeks of August you can come and work at our lab, using our printers and knitting machines! We will have staff available to help you and give you advice, but it is not a course, you will be working independently, like in a fab lab.

You will get your own spot to work, access to the machines and materials that we have, and you will also be able to browse our private library with thousands of books on footwear design and history, as well as art, textiles and other materials, biotechnology, architecture etc.

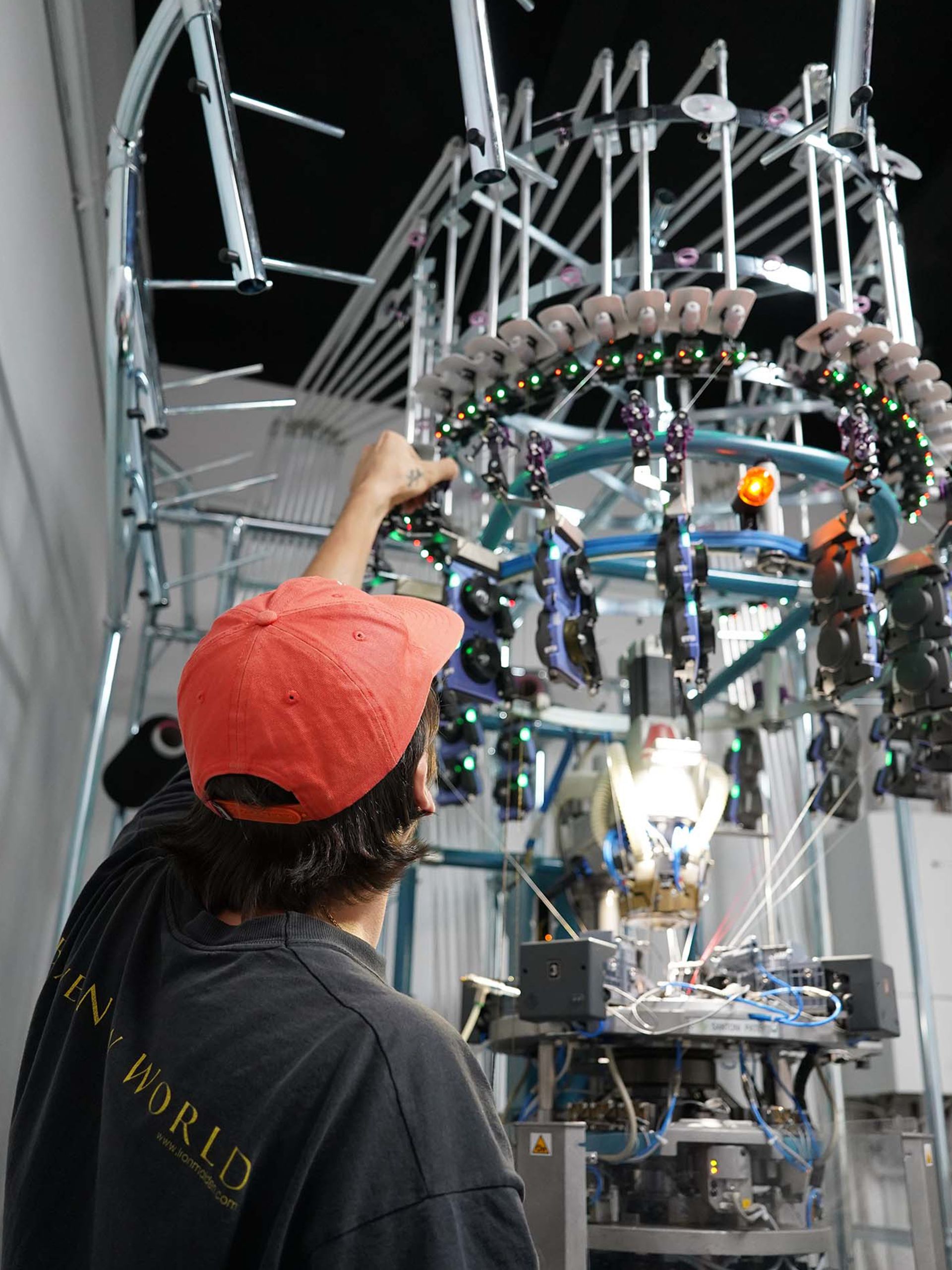

We have several different options, depending on when and how long you want to be there and which machines you want to have access to. You are not allowed to operate our knitting machines by yourself, but you can explain your wishes to our programmer and choose from the selection of yarns we have available.

For just printing we can have 4 people per week, but for knitting only 2, since the programming takes more time. Reserve your spot now through the buttons below. If you want to come for two weeks, then please enroll separately for each week.

If you book before June 30 you pay 100 euros less!

In the last two weeks of August you can come and work at our lab, using our printers and knitting machines! We will have staff available to help you and give you advice, but it is not a course, you will be working independently, like in a fab lab.

You will get your own spot to work, access to the machines and materials that we have, and you will also be able to browse our private library with thousands of books on footwear design and history, as well as art, textiles and other materials, biotechnology, architecture etc.

We have several different options, depending on when and how long you want to be there and which machines you want to have access to. You are not allowed to operate our knitting machines by yourself, but you can explain your wishes to our programmer and choose from the selection of yarns we have available.

For just printing we can have 4 people per week, but for knitting only 2, since the programming takes more time. Reserve your spot now through the buttons below. If you want to come for two weeks, then please enroll separately for each week.

If you book before June 30 you pay 100 euros less!

Is this an opportunity for YOU?

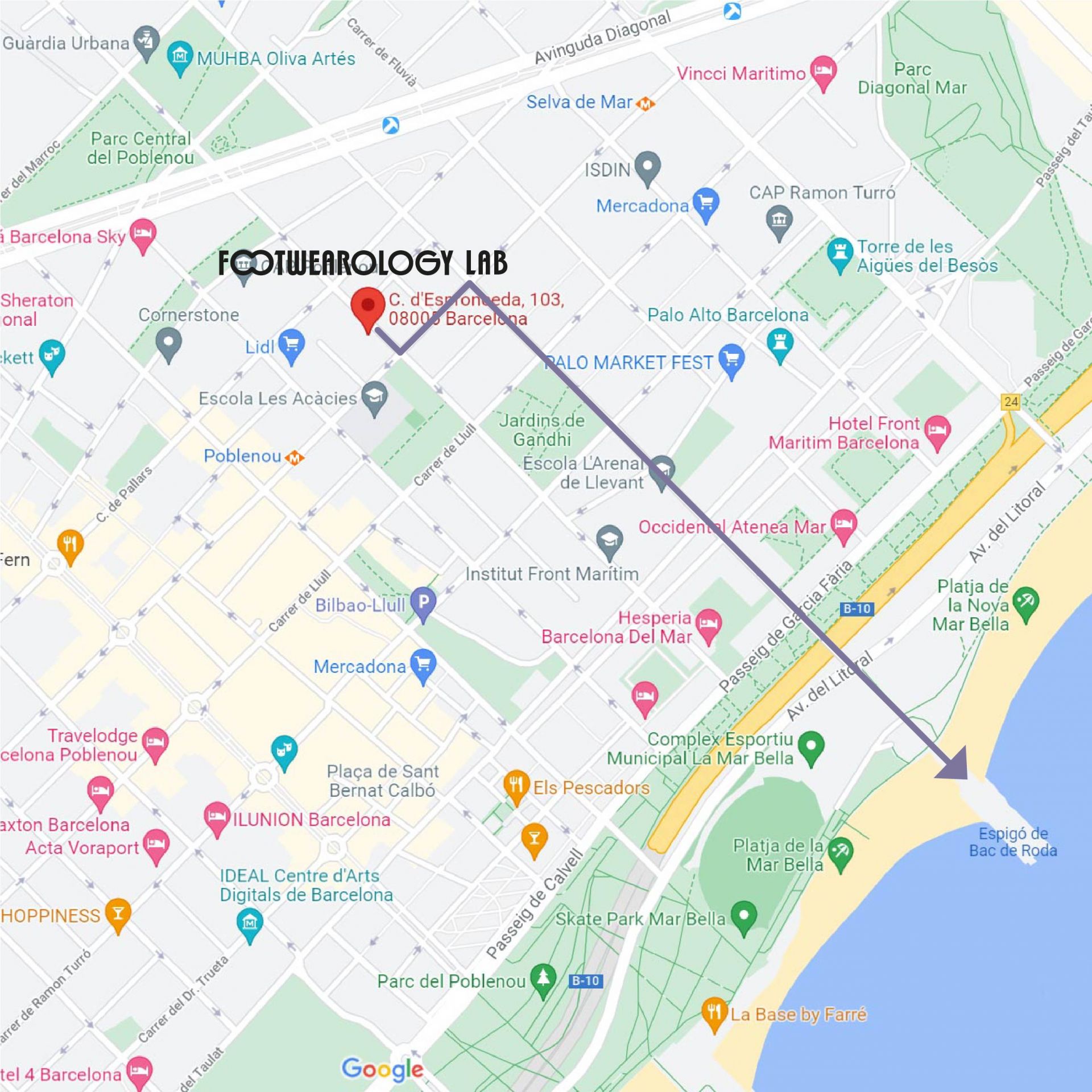

Practical information

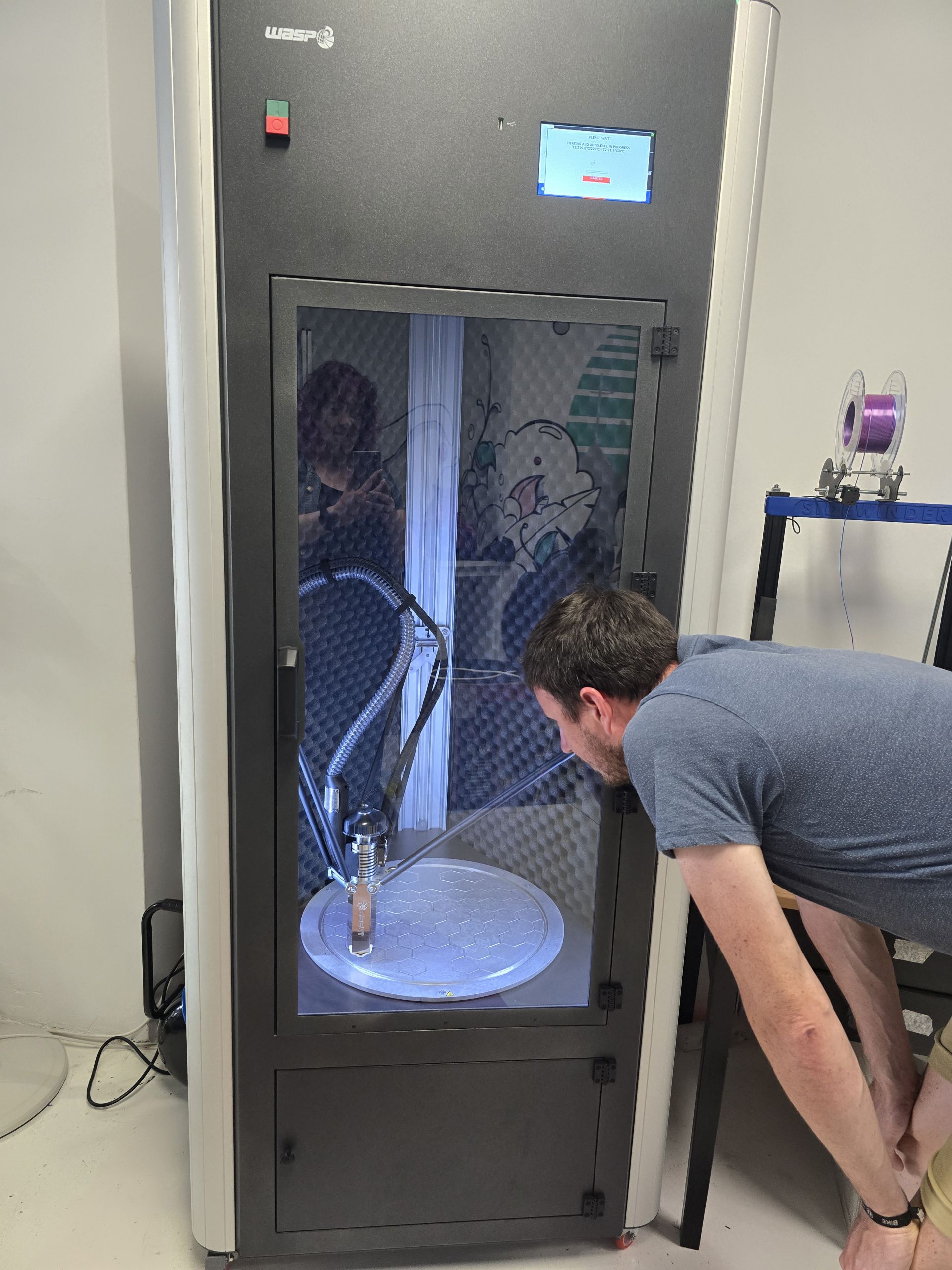

Our machines