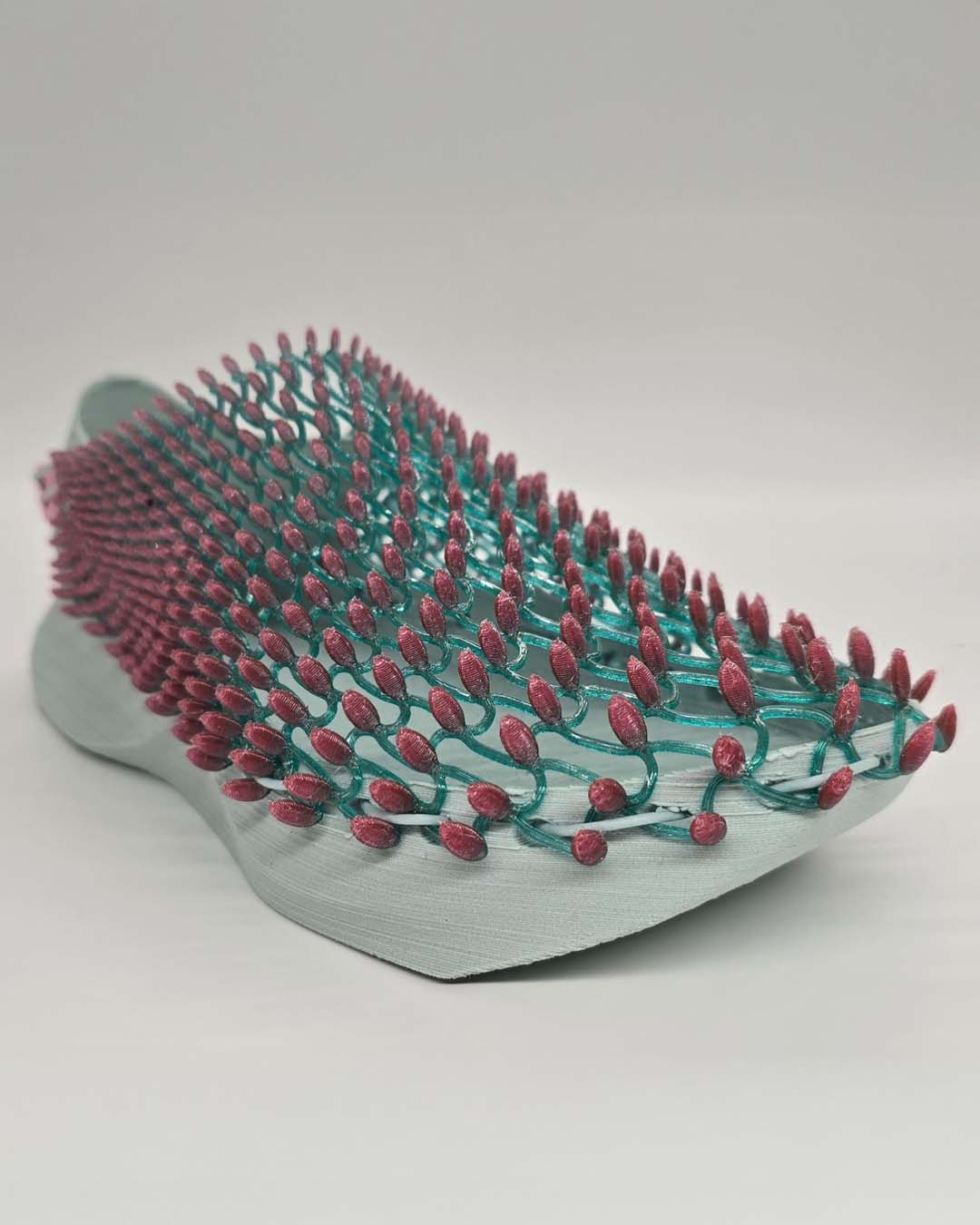

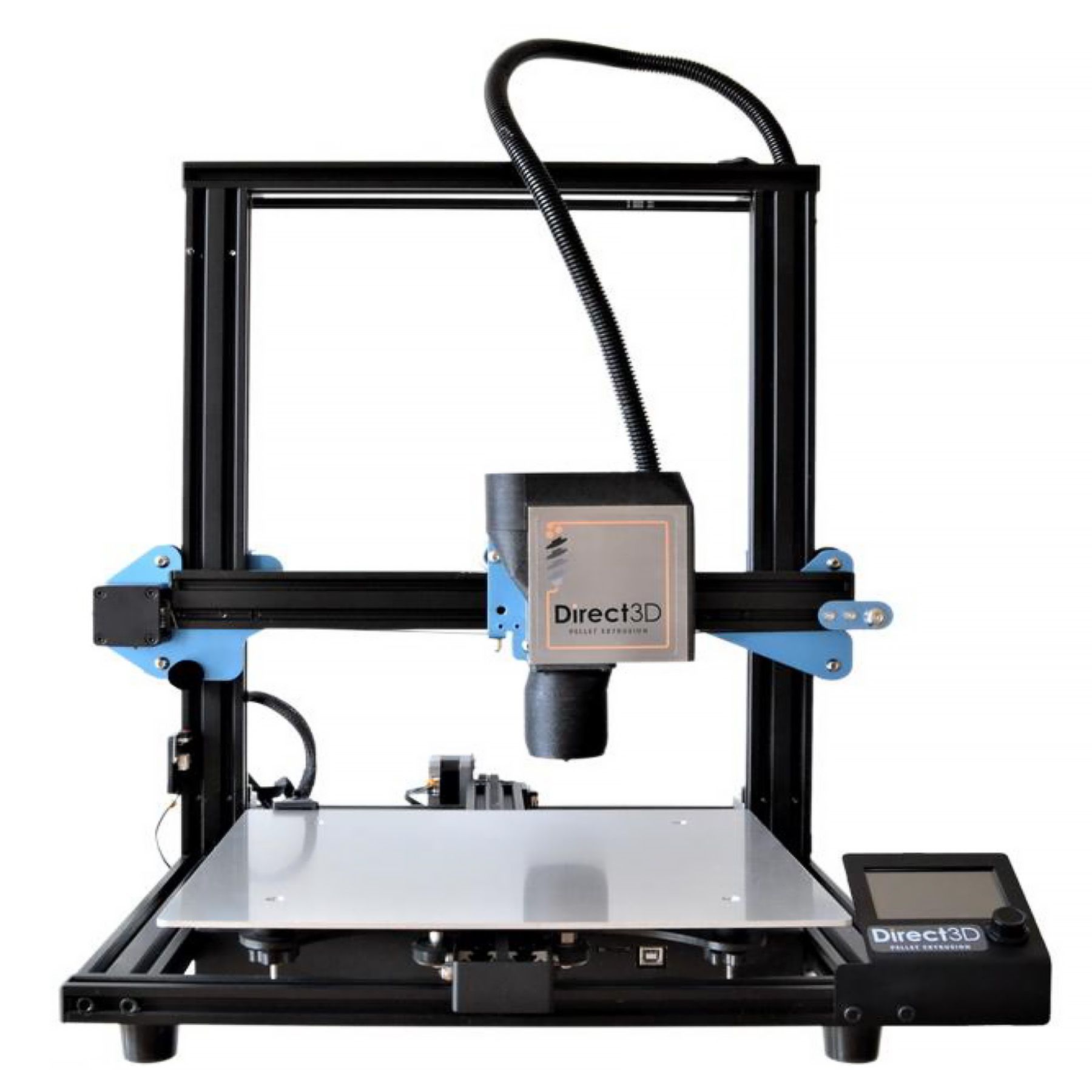

3D printers are the core of our lab, we specialize in printing flexible footwear that is affordable and comfortable. We use FDM machines - both with filament and pellets - so the material can be recycled. We are beta testers for new materials and machines, so we always have the latest technologies in house.

In the front of the lab we have a space for small classes or meetings and here we show the history of 3D printed footwear, with examples of almost all essential past and current 3D printed shoe brands, not just in FDM, but also in powder and resin.

Our large library - with spectacular sea views - has a unique collection of books on footwear and sneaker history, design and technology, as well as a fantastic selection of books on materials, industrial design, art and architecture. It has a big work table for larger meetings or classes, as well as a big TV screen for presentations.